ADA Push Button Guidance

Excerpted from: https://www.access-board.gov/ada/guides/chapter-3-operable-parts/

This guide explains requirements in the ADA Standards for operable parts.

Notational tips for users of screen reading software follow. In this document ″ indicates inches and ′ indicates feet. Some images are paired with visually hidden notes.  These annotations are prefaced with begin and end image notes.

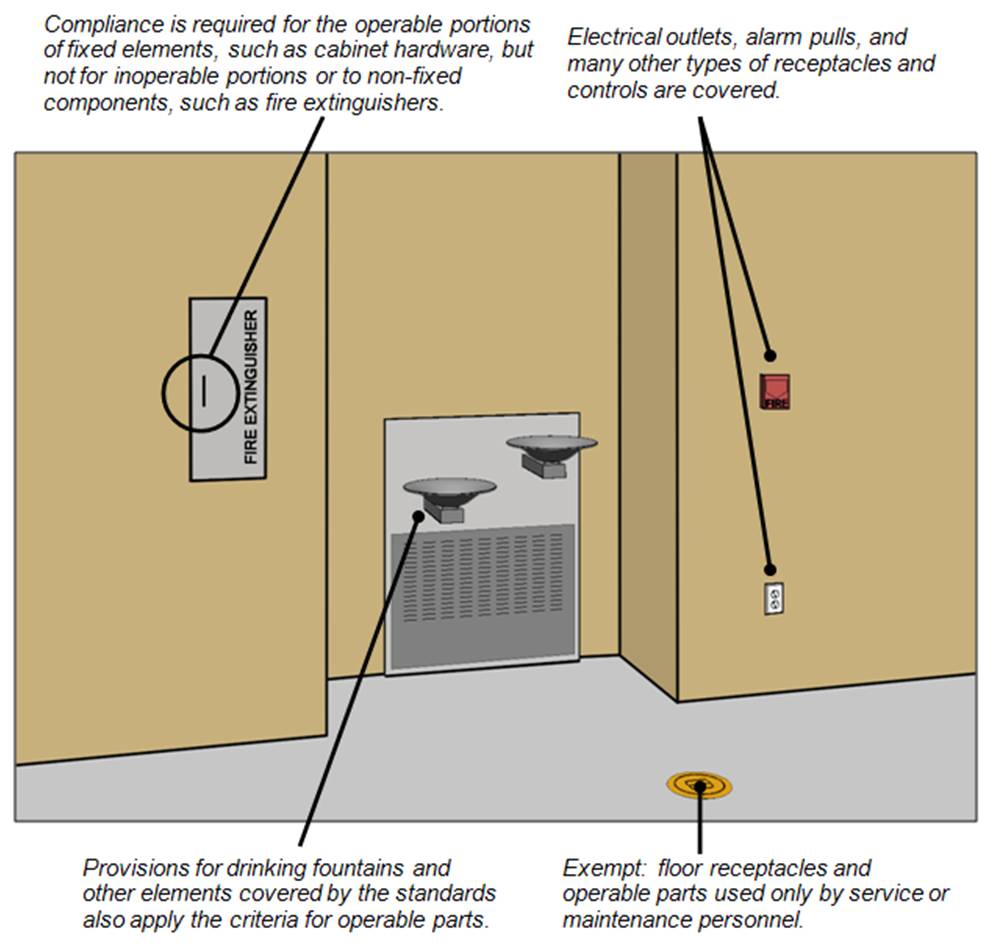

Operable Parts Covered

[§205]

Compliance is required for operable parts located in accessible spaces and along accessible routes. Operable parts include light switches, electrical and communication receptacles, thermostats, alarm pulls, automatic door controls, and other elements used by facility occupants.

Examples of Operable Parts

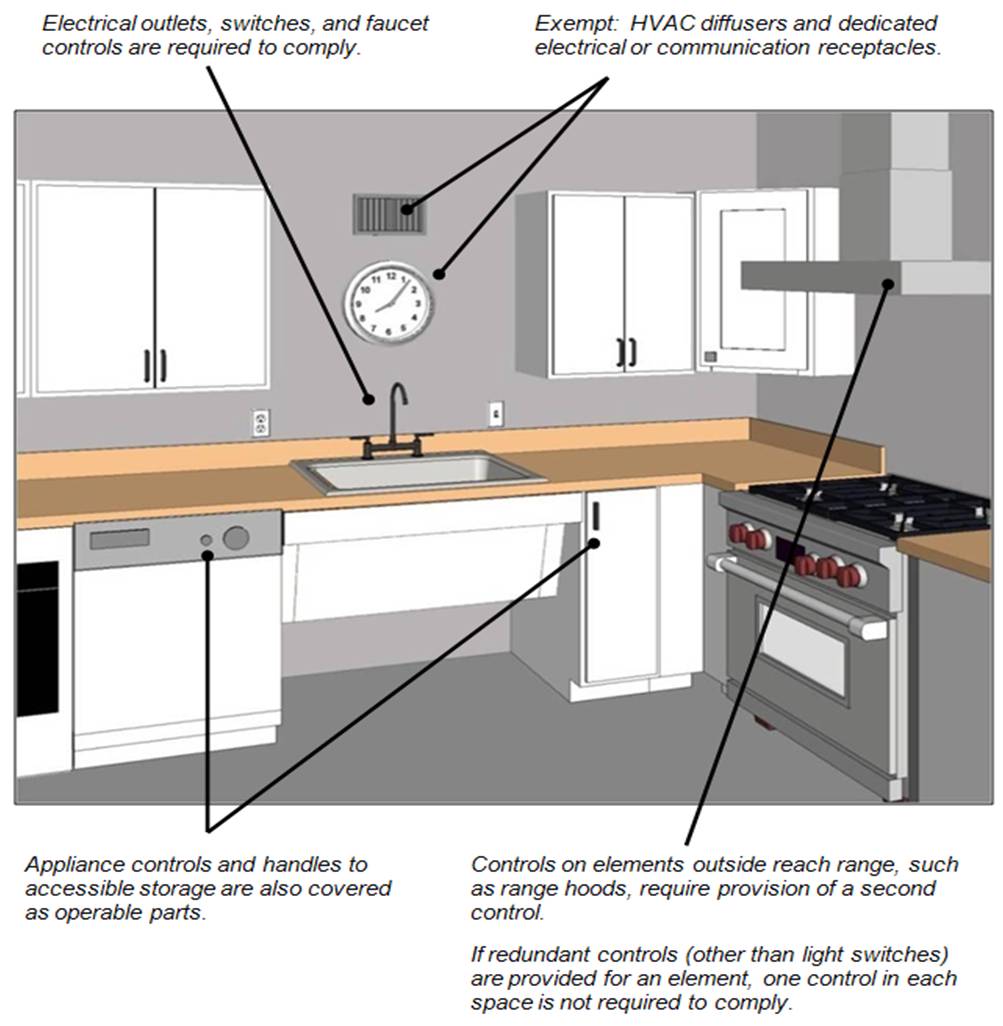

Examples of Operable Parts in Kitchens

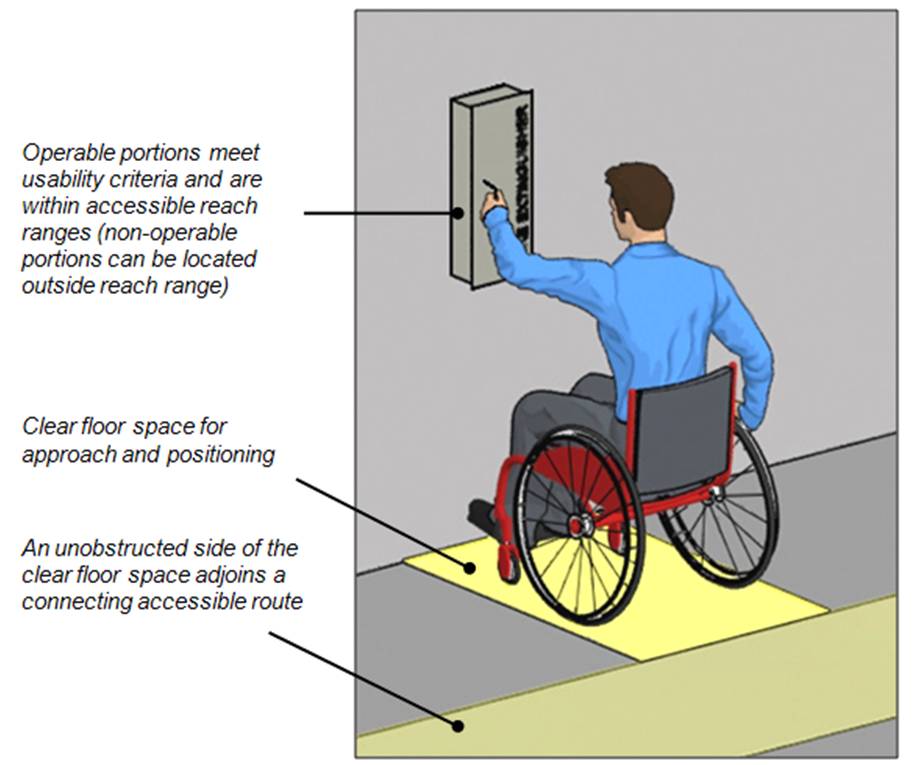

Operable Parts

[§309]

Requirements apply generally to all types of operable parts covered. They are also referenced by technical sections of the standards covering drinking fountains, faucet and flush controls, ATM and fare machines, appliances, storage, windows, and door and gate hardware, and other elements.

Accessible Features of Operable Parts

Forward and Side Approaches

At most elements, clear floor space can be positioned for either a forward approach or a side approach. A forward approach is required at some elements, such as drinking fountains and lavatories, for easier access.

Forward Approach and Reach

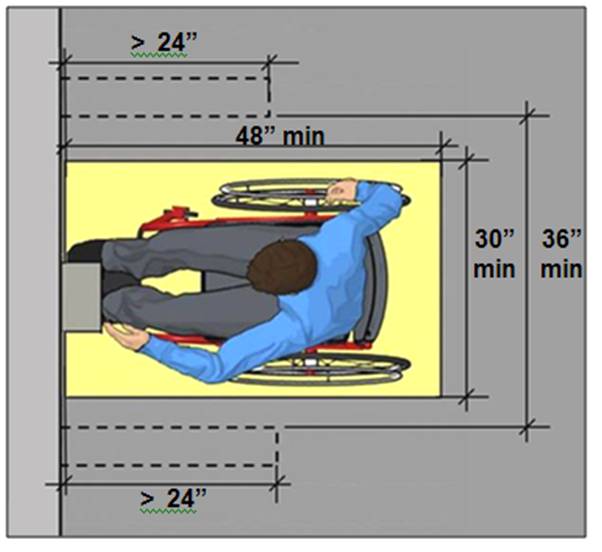

Clear Floor Space

[§309.2]

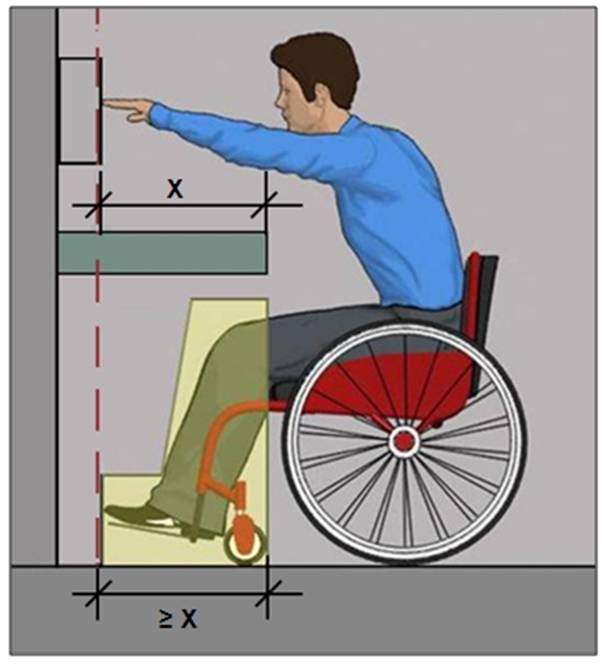

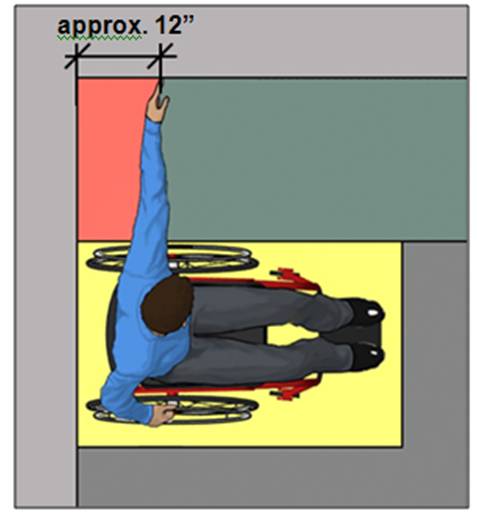

Clear floor space for forward approaches must extend up to or, if knee or toe space is provided, below operable parts. This facilitates access since the forward reach does not extend beyond a wheelchair user’s toes.

If clear floor space is obstructed on both sides more than half the minimum required depth, a wider clearance (36″ minimum) is required for maneuvering and sway.

Knee and Toe Space

If the forward reach to operable parts extends over an obstruction, such as a counter, clearances for toes and knees is required below. The knee and toe space must be at least as deep as the reach depth measured from the leading edge of the obstruction.

Forward Reach

[§308.2]

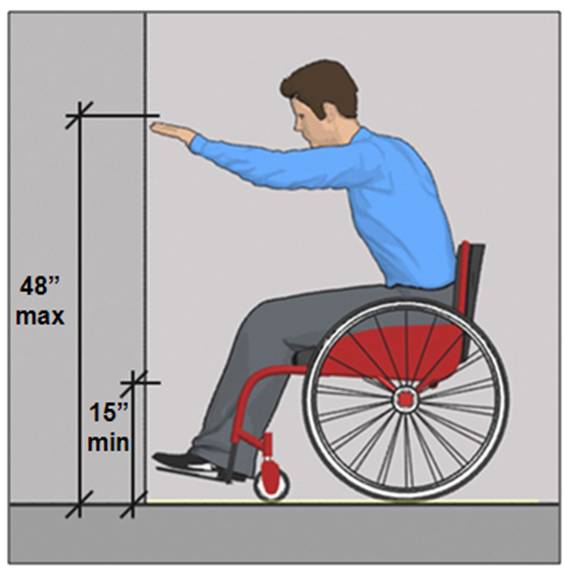

The range for unobstructed reaches (15″ to 48″) applies only to those portions of elements that are operable. Non-operable portions can be located outside the range.

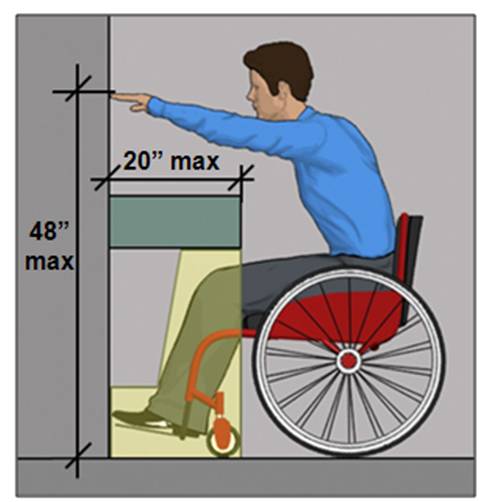

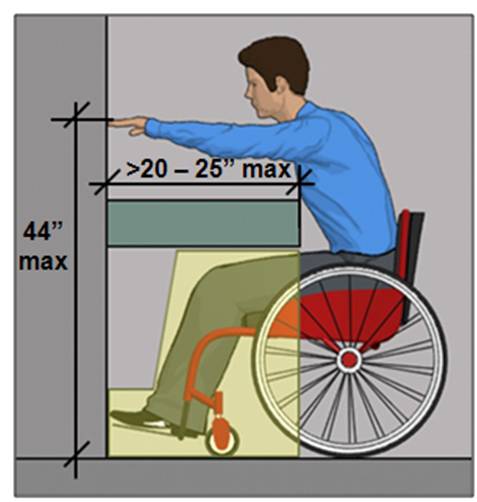

Obstructed High Reach

The maximum reach of 48″ is reduced to 44″ when the depth of reach over an obstruction exceeds 20″. Knee and toe space must extend the full depth of reach.

Side Approach and Reach

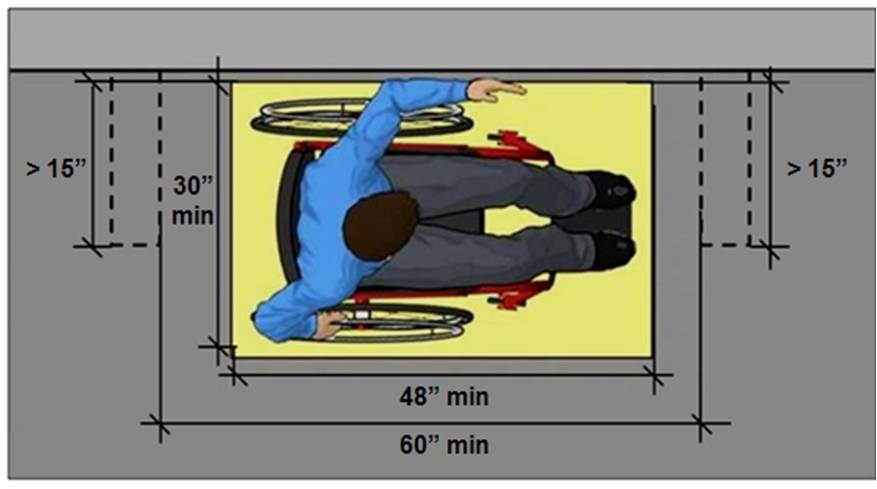

Clear Floor Space

[§309.2]

Clear floor space can be oriented for a side approach instead of a forward approach at most operable parts. Nominal centering of the space on operable portions of elements is advisable, but not required (except at washers and dryers).

Additional clearance is required if the space is obstructed on three sides for more than half the depth to allow easier maneuvering into the space.

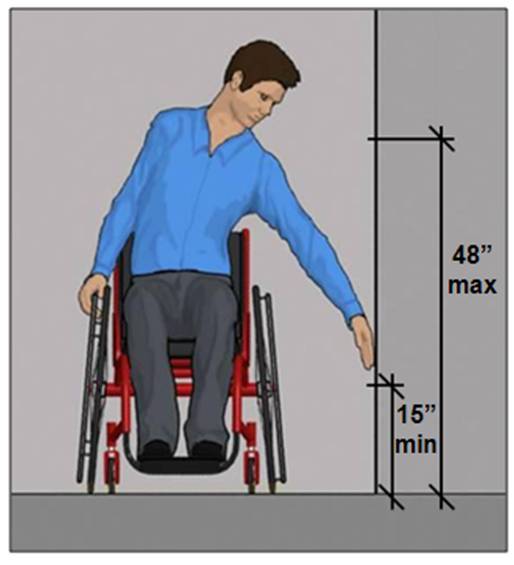

Side Reach

[§308.3]

The range for side reach, like forward reach is 15″ to 48″ if unobstructed. The maximum reach depth for this range is 10″ measured from the available clear floor space.

Fuel Dispensers

The operable parts of fuel dispensers located on existing curbs can be up to 54″ high.

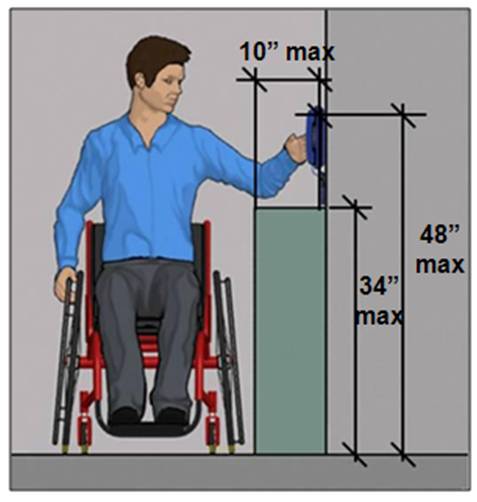

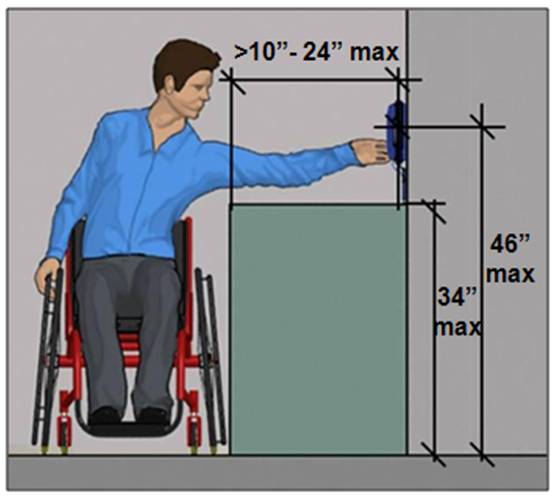

Obstructed High Reach

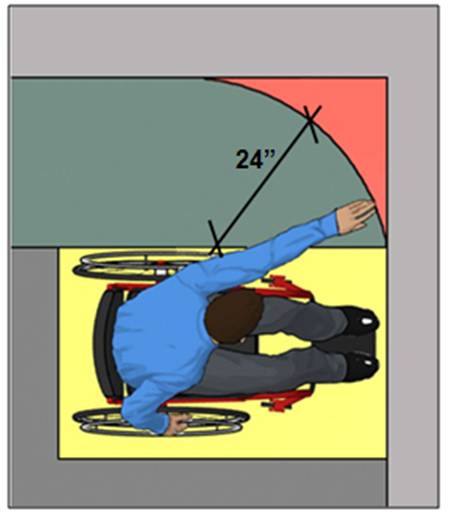

The maximum high reach is reduced to 46″ when the reach over an obstruction is deeper than 10″ (to a maximum of 24″). Obstructions at side reaches are limited to a height of 34″.

Side Reach Radius

Elements located in corners can be difficult to reach from a side approach.

Recommendation: Where a side reach is provided, locate elements away from corners in consideration of the typical reach radius.

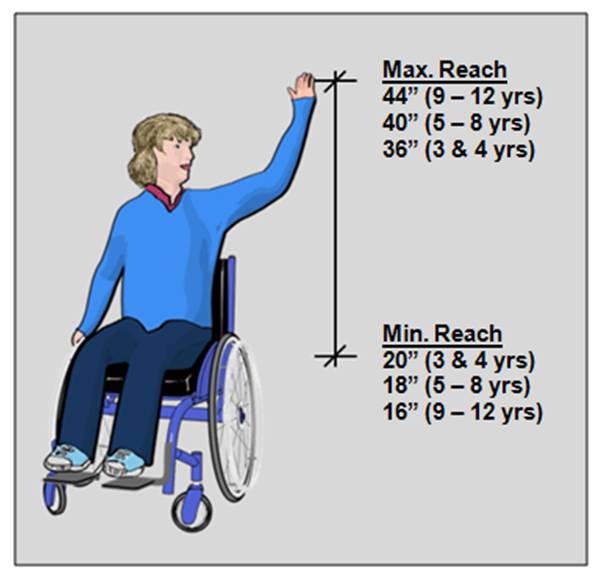

Advisory Reach Range for Children

The standards include advisory (non-mandatory) reach ranges based on children's dimensions that can be followed when operable parts are designed for use by children. This guidance provides reach ranges recommended according to three age groups.

The standards include advisory (non-mandatory) reach ranges based on children's dimensions that can be followed when operable parts are designed for use by children. This guidance provides reach ranges recommended according to three age groups.

Operation

[§309.4]

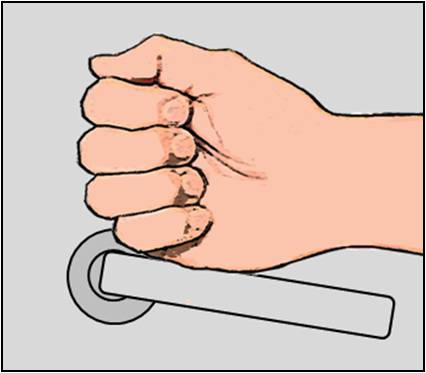

Operability with a closed fist is a reliable test of usability, but is not required by the standards.Operable parts must be usable with one hand and not require:

Operability with a closed fist is a reliable test of usability, but is not required by the standards.Operable parts must be usable with one hand and not require:

- tight grasping, pinching, or twisting of the wrist, or

- more than 5 pounds of force (lbf) to operate.

Parts that can be operated without hand or finger dexterity, fine motor movement, or simultaneous actions provide easier access and accommodate a broader range of users.

Push Plates, Buttons, and Bars

Push-activated controls not requiring more than 5 lbf are acceptable. Buttons that are raised or flush are easier to use than those that are recessed. (Elevator control buttons cannot be recessed, and input keys at ATM and fare machines must be raised.)

Handles, Pulls, and Knobs

Standard U-shaped pulls and lever-shaped handles are acceptable. Stationary knobs with a shape that can be loosely gripped also are acceptable. Knobs that require a full hand grip and turning, including round door knobs and shower controls, do not comply because they require twisting of the wrist.

Latches and Locks

Latches and locks with small parts that must be manipulated can be difficult to use and will not comply if pinching is necessary. However, non-fixed portions of locks and other operable parts, such as keys and access cards, are not required to comply (but those that do not require pinching or turning provide better access). Hardware that does not require simultaneous actions are better, but some types, such as handles with thumb latches are acceptable.

Controls and Switches

Dials and other controls that can be turned with the fingers but not the full hand can be used if they do not require twisting of the wrist or pinching. Flip switches and similar controls are acceptable, though push plate types can provide easier access.